-Anirudh Gupta, CEO, Jindal Blades

Bread is one of the oldest prepared foods since 10,000 BC and its worldwide consumption has increased ever since. Baked bread is the ‘oldest man-made staple food’ in the human diet and is integral to human health with plenty of major nutrients, antioxidants and vitamins. After thousands of years, it still remains the most regularly consumed food in the world, due to its convenience, portability, nutrition, taste and affordability.

WITH GREAT DEMAND COMES GREATER TECHNOLOGY

Sliced bread was first introduced to the world in 1928. Then, we humans started mass-producing bread in commercial bakeries and with the passing decades’ newer technologies and improved machinery were innovated to meet the rising demand. However, the health safety standards of the bread sometimes get neglected in this rush to produce more and more bread. Nowadays, consumers are more ‘health-conscious and aware than ever about what they eat and how every food item will affect their overall wellbeing.

As of date, there are only ‘two types of machines’ on which bread can be sliced:

1. Reciprocal Slicer Machine (also commonly known as high-speed slicers)

2. Band Slicer Machine (a newer and more efficient technology for automated bread production)

CATEGORIES OF BREAD MANUFACTURERS

1. Commercial Or Industrial Bread Factories (famous bread brands we buy from the market)

2. Artisan Bakeries (small bakeries usually having a limited number of outlets in their locality)

3. Home Chefs Or Bakers (this category usually produces bread for their own use or for supply in their catering orders)

Universally, the cutting edge used to ‘slice bread’ is known as ‘a scalloped or serrated or concave teeth’. This unique ‘concave teeth cutting edge’ enables slicing through soft food products easily by pulling the blade across the food product with minimal crumb formations. More than 90% of reciprocal and band slicer blades used around the globe have these concave teeth, which are used to slice bread.

We at Jindal Blades have a vast experience in metallurgy, steel manufacturing and production of cutting blades. My grandfathers were the first in India to manufacture ‘high carbon – hardened tempered steel strips’ and ‘wood bandsaw blades’ in the 1960s and 1970s. These products were being imported until then.

Ironically, history has been repeated in 2022, as we at Jindal Blades are the first in India to supply band slicer blades for bread. Yes, that is correct. Surprisingly, the band blades used to slice bread in-band slicer machines are not manufactured in India yet! Further, reciprocal stainless steel blades are also not available in India. Jindal Blades have now developed indigenous bread slicer blades for these two ‘import substitute products.

PROBLEMS TODAY IN INDIA’S BREAD INDUSTRY

All the Indian bread companies today are only concerned with fulfilling their daily production targets. With regards to slicing, their only necessity is that they continue receiving their ‘size’ of ‘bread slicer blades’ or else their production gets hampered.

Further as per our experience; throughout India, there is not even a single ‘bread slicer blade’ ‘manufacturer’ which understands the steel properties/ chemical analysis or even the mechanical scalloped teeth which are the primary and only cutting edge used to slice bread across the globe.

Presently in India, bread slicer blades are being manufactured not only from low-grade carbon steel but also from recycled packaging strips and un-approved cheap quality mild steel, which is not only inappropriate but also harmful as per food contact material standards.

Today, the bread manufacturers in India are continuously trying to beat inflation and sustain the market price of bread. Further, yes India is a more affordable country than the developed world. But if the prices of bread slicer blades are compared, India cannot be 6-10 times cheaper! For example, the average cost of a reciprocal blade in India ranges from INR 10 to INR 20 per blade, the minimum cost of a reciprocal blade in most developed countries is INR 65 to INR 75 per blade. High-quality blades are also being sold for as high as INR 200 to INR 300 per blade in these developed countries. Even China is producing and supplying reciprocal blades at a minimum cost of INR 50 per blade. Therefore, Indian bread companies should refrain from the use of inferior quality blades and prioritise health safety.

PROBLEMATIC AND FACTUAL POINTS

1. Reciprocal bread slicer blades being a ‘consumable product’ are generally replaced every 6 hours at high production bread factories; every 7 – 10 days at medium-scaled bakeries and every 1.5 – 3 years at artisan bakery outlets

2. “Re-grinding” of reciprocal blades is the biggest cause of concern as the ‘burr metal particles’ get mixed in the bread i.e. Metal contamination. (even the biggest bread companies of India re-grind the blades un-professionally and that too multiple times)

3. Most of the bread factories re-grind every blade at least 4 to 6 times! The steel burr formed every time a blade is re-sharpened allegedly enters the bread and in-turn can affect the heath of the consumer.

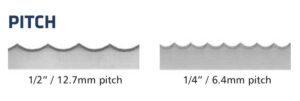

4. For example; a new reciprocal bread slicer blade has a width of 12.7 mm, but after it has been ‘re-used multiple times’ the remaining blade width is only about 7-8 mm.

5. While slicing bread; the blades are not just in contact with bread; but they are in continuous friction and they rub against the bread. (slice through) (this exceeds the food contact material standards)

6. Small bakeries, which have a very low production output everyday (the ones that slice about 50 to 300 loaves per day); change the blades once in every 1-3 years. In such cases, the carbon blades are prone to rust and will definitely cause undesirable disadvantages, which can be injurious to human health!

7. 100 % of reciprocal blades used in India are made of low quality carbon steel and are not approved by FCMS regulations.

8. FSSAI recommends that isopropyl alcohol be used to disinfect every equipment that comes in contact with food. (carbon steel when cleaned and dried develops a tendency to form rust on its surface) (whereas, food-grade stainless steel is non-corrosive)

9. Using stainless steel blades will only add to safety benefits and have no drawbacks!

10. Using SS blades is a precaution and prevention is better than cure!

11. Food grade stainless steel has higher temperature resistance and is a better choice for bakery slicer blades as bread is sliced when it is hot, warm and moist.

12. Carbon blades need to be ‘oiled’ at all times and not every bread manufacturer has the awareness to do the same

13. Stainless steel does not need to be ‘oiled’ and performs uniformly in all climatic conditions and geographical locations

14. Bread is mostly 60% moisture and also has numerous additives, preservatives, chemicals, acidity regulators, etcetera, which react with carbon steel blades faster

15. Indian coastal cities have a higher possibility of blade rusting

16. In high speed band slicer machines, the re-sharpening of band blades is professionally done at high speeds in the machine itself using tools installed by the machine manufacturers itself. But in the case of reciprocal slicer blades, manual re-sharpening is risk-causing and is a cause of concern!

CALL FOR ACTION

“Stainless steel bread slicer blades” should be mandated across India. Stainless steel does not rust and has high corrosion resistance. When ‘stainless steel blades’ are used, they act as an ‘anti-bacterial tool’ to reduce contamination between slices. Re-grinding of stainless steel blades will prove to be difficult for the bakeries, which will help in preventing external contamination sources.

Since re-grinding is a potential source of ‘trace metal contamination’ and ‘bacterial contamination’ to the bread; ‘disposable’ bread slicer blades should be promoted and made compulsory in India.

India should take inspiration from the more stringent food safety regulations of the western world/ EU commission and “prohibit dual-use of potentially harmful equipment” which comes in contact with food. (like the UK has done).

Every new or re-sharpened blade, after grinding should be de-burred, sanitised and oiled (in case of carbon blades).

Most importantly, the ‘FSSAI’ should launch an immediate survey and inspect the actual on-ground situation of the major bread companies and issue new safety guidelines in the interest of Indian bread consumers to specifically promote the use of stainless steel blades and discourage re-grinding of blades.

We are not trying to prove that bread in India is already contaminated. We are only trying to focus the attention of the bread manufacturers and bread consumers to a potential source of health risk and improve the safety standards of the bakery industry and spread awareness, provide a solution and support the bakery equipment manufacturers and bakeries.

We at Jindal Blades are dedicated to serving the bakery industry and promote healthier slicing of bakery products by using stainless steel blades at the cheapest possible prices.

(The opinions expressed in this article are those of the author and do not necessarily reflect the official views of KitchenHerald.com or associate portals.)