KH News Desk (intern@imaws.org)

The plant-based food industry grew by 49 per cent between 2018 and 2020, according to the Smart Protein Project. In contrast, plant-based beverages are widely recognized in Asia not only as an alternative to dairy products but also as an important nutritional beverage. Given the region’s high rate of lactose intolerance — about 80 per cent of Asians are unable to properly digest lactose — the demand is perhaps not surprising. Soy milk has a history of more than 2,000 years and is a staple of East Asian culinary traditions. However, the soy milk beverage category faces challenges for future growth in the Asia-Pacific region, mainly due to modern consumption habits and the desire for product diversification. Younger generations perceive soy as a more traditional beverage and choose alternative products. As our 2021 Tetra Pak Index shows, consumers are increasingly health-conscious and more sustainable, looking for a wider range of natural foods with a lower environmental impact. Plant-based beverages have become a popular choice for those looking for healthy options or variety in their diet.

The challenge for food and beverage brands is to meet this growing demand without compromising taste or nutritional value. To meet this challenge, Tetra Pak has developed a revolutionary technology. This non-traditional processing method, known as “whole soybeans,” uses the entire soybean in production with no waste stream. But how does the final product differ from traditional soy beverages?

The main difference between “whole” soy products and “conventional” soy products is processing. Traditional production techniques of soy beverages include the separation of the fibrous component okara at the filtration stage, which means a loss of 20-30% of the total protein. Given that soy beverages are valued for their protein content, this represents a significant loss of nutritional and economic value for beverage manufacturers. Tetra Pak’s new technology eliminates this waste by including the insoluble part of soy fibres in the drink, thus ensuring a higher protein content in the final product.

Whole beans contain a higher percentage of fibre and more protein and are lower in calories than regular soybeans. This allows soy beverage manufacturers to capitalize on the growing trend among consumers to choose healthier products. For example, a 100% whole soy drink contains 1.2% fibre, compared to 0.26% extracted soy and 0% milk. There is also a debate about the taste of using whole beans, with preliminary studies showing that whole soy products are considered creamier than regular soy and closer to “fresh” soy than other alternatives in the traditional market.

This processing method is also good for the environment. The production of soy products by traditional methods produces a large number of okara by-products that must be disposed of as waste. For every 1 kg of soybeans used in production, approximately 1.5-1.7 kg of by-products are produced. Re-incorporating okra into the final beverage can reduce waste and reduce the financial burden on producers. The result is a more nutritious product with lower raw material costs and lower waste disposal requirements.

Coping with treatment problems: At Tetra Pak, we strive to understand how processing affects beverage properties such as taste, product viscosity, product stability and nutritional value, and how they interact to form the final product.

Coping with treatment problems: At Tetra Pak, we strive to understand how processing affects beverage properties such as taste, product viscosity, product stability and nutritional value, and how they interact to form the final product.

Take taste as an example: soy drinks contain lipoxygenase, which creates a characteristic aroma and a characteristic aftertaste. The entire soybean processing method allows producers to change this flavour with minimal effort, allowing producers to create different flavour profiles and appeal to multiple consumer groups.

Texture or “mouth feel” is another challenge to address. In the past, smoothness issues were difficult to overcome when developing whole bean fibre products. At Tetra Pak, we take our understanding of manufacturing – studying soybeans and their varying protein content and enzyme activity – and combine this with our processing technologies to create a solution that produces quality-consistent, high-quality whole bean beverages. co-creation with customers.

Whole soybeans are a new product category and each customer case is unique with specific requirements. Overcoming processing challenges requires collaborative innovation, so we work closely with our customers to experiment and trial different iterations through our product development centre. One such example is our partnership with Taiwanese food and beverage manufacturer I-Mei to develop a total soy processing solution to capture the okara byproduct and add it to their soy milk beverages. By experimenting with different grinding solutions, we can reduce the particles to the desired size. the result?

A fibre-rich product with no added sugar, good taste and a perfectly smooth texture. Since then, more Asian customers have adopted the technology. Now they can highlight the health benefits of their products while highlighting the new creaminess and texture. There are already several full soy production lines around the world, and we expect demand to grow as more brands look to use less wasteful processing to produce healthier lines. Packaging also plays a vital role in this space. Aseptic packaging solutions can significantly extend the shelf life of beverages, as soy-only beverages typically last 6 to 12 months without the need for preservatives or refrigeration. It provides access to safe food by enabling food producers to reach consumers in more remote areas – in line with Tetra Pak’s commitment to making food safe and accessible everywhere.

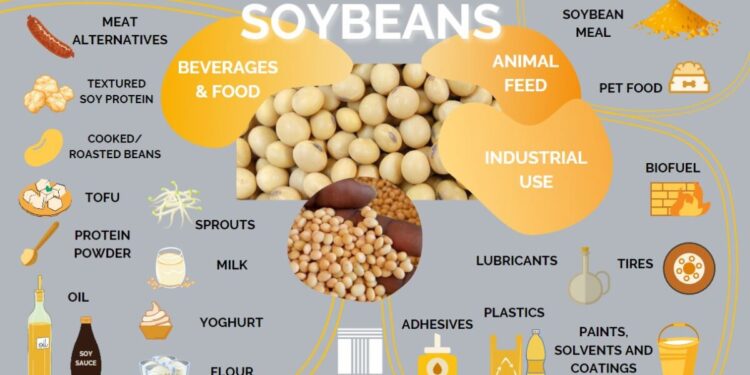

The entire line of soybeans used the same method to pave the way for a wide range of new products such as yoghurt, pasta, ice cream and meal replacements. Although we have focused on beverages so far, we plan to use this as a springboard for innovation across multiple products. Consumers benefit from a healthy diet of whole soybeans that are very close in sensory aspects to traditional soybean products. At the same time, brands have the opportunity to fill market gaps with the ability to refine them according to specific requirements.